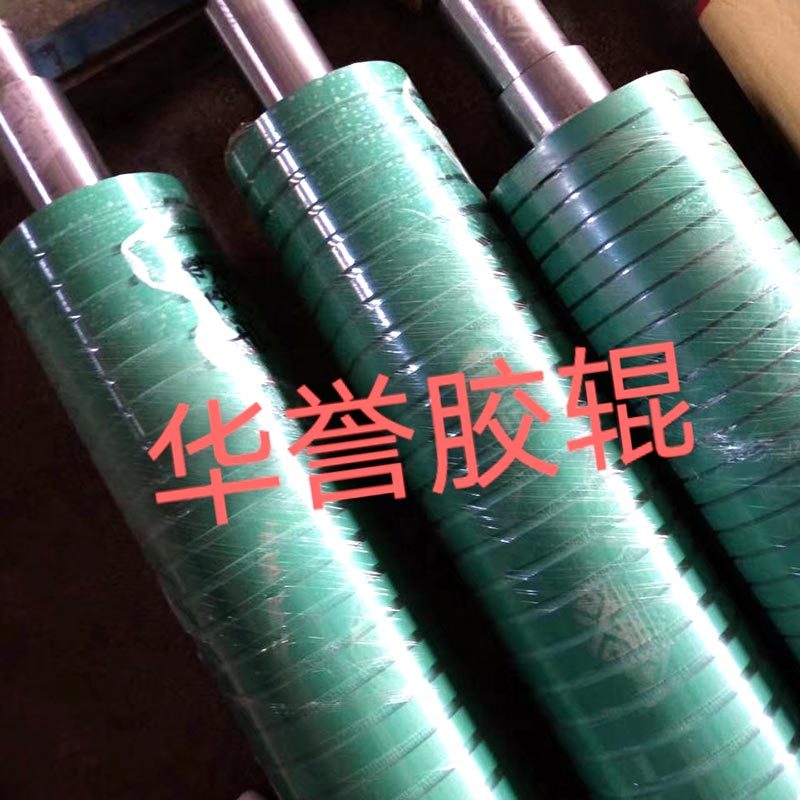

Cheap printing rubber rollers

Dongguang yongcai rubber roller co., ltd. produces transmission rubber roller, rubber roller coating, rubber shaft, polyurethane rubber roller, laminating machine rubber roller, rubber rubber roller, industrial rubber roller, printing rubber roller, rubber roller manufacturer, rubber roller and other products. the company's products have involved five series and more than 100 varieties.

Key words:

Description

Printing rubber rollers are integral parts of the printing process, playing a crucial role in achieving precise and consistent print results. These rollers are designed with specific characteristics to ensure optimal performance in various printing applications.

The rubber used in these rollers is carefully selected for its unique properties. It provides a soft and compliant surface that allows for smooth contact with the printing medium, whether it's paper, fabric, or other materials. This helps to transfer the ink or other printing substances evenly, minimizing streaks and ensuring sharp, clear images.

One of the significant advantages of printing rubber rollers is their ability to adapt to different printing techniques and machinery. They can be used in offset printing, flexographic printing, gravure printing, and more. Each type of printing requires rollers with specific hardness, surface finish, and diameter to ensure compatibility and high-quality output.

The manufacturing process of these rollers is a combination of precision engineering and advanced technologies. Skilled craftsmen ensure that the rollers are precisely shaped and sized to fit the printing equipment accurately. The surface of the rollers is treated to achieve the desired level of smoothness and texture, which directly affects the quality of the print.

Printing rubber rollers also need to be resistant to various factors such as wear and tear, chemicals, and temperature changes. High-quality rubber compounds are used to enhance their durability and longevity, reducing the need for frequent replacements and minimizing downtime.

In addition to their technical specifications, these rollers also need to be maintained properly. Regular cleaning and conditioning are essential to keep them in optimal condition and prevent any build-up of ink, dirt, or other contaminants that could affect the printing quality.

Moreover, customized printing rubber rollers are available to meet the specific requirements of individual printing operations. This allows for fine-tuning the rollers to the exact needs of a particular job, ensuring the best possible results. Whether it's a specific hardness level, a particular surface pattern, or a unique size, manufacturers can create rollers that are tailored to the specific demands of the customer.

In conclusion, printing rubber rollers are the unsung heroes of the printing industry. Their quality and performance directly impact the final printed products, and by choosing the right rollers and maintaining them properly, printers can achieve outstanding results and meet the highest standards of quality in their printing operations.

Inquiry

Yongcai Rubber Roller

Message